RV Maintenance and What You Need to Know About Your RV’s Fluids

The gas or diesel powered RV you’ve purchased was likely no small investment, and while it is going to depreciate over time, if you’re like many RV owners we’ve talked to, protecting your investment both for your enjoyment and potential resale value is a key concern.

The gas or diesel powered RV you’ve purchased was likely no small investment, and while it is going to depreciate over time, if you’re like many RV owners we’ve talked to, protecting your investment both for your enjoyment and potential resale value is a key concern.

We all know keeping up with regular and necessary maintenance on your RV is critical, but something that many RV’ers are not aware of is that testing your RV’s key fluids can provide information about the real health and operating performance of your components. Not only that, it’s easy and relatively inexpensive. Specifically, depending on how your RV is equipped, we’re talking about the analysis of your RV’s power systems:

-

Engine Oil

-

Transmission Oil

-

Engine Coolant

-

Generator Oil

-

Generator coolant

Engines

So what kind of information do you get from analyzing these fluids? There are three main factors that a fluid analysis will measure, which will inform you about the current oil life as well as indicate problems that may be taking place in your equipment. They are:

- Viscosity – which is defined as the thickness of the oil or resistance of an oil to flow at a given temperature.

- Oxidation – which indicates how much heat the oil has absorbed since the last change.

- Contamination – which measures the amount of contaminants or debris that may be present in the oil such as fuel, coolant, wear metals etc.

(For additional detail read: All About Oils for RV and Tow Vehicle Owners)

Cummins outlines the benefits of engine oil analysis as part of their Fleetguard business as follows:

- Determines metal content, alerting you to wear occurring in pistons, liners, cams, valves and other engine, transmission and equipment components.

- Signals air/fuel ratio problems which can lead to poor fuel economy and reduced air cleaner efficiency. Warns of oil thickening, diminished oil heat transfer and reductions in flow. Also detects coolant leaks.

- Identifies fuel system malfunctions such as fuel line leaks, worn rings and injector or pump problems.

While you might be particularly good at staying on top of your engine oil changes based on recommended miles/time/hours, you might be throwing out very important information that could alert you to potential problems that you may not otherwise detect until it’s too late.

Oil degradation and contamination can only be properly assessed through periodic monitoring through oil analysis. This information could save you from a major failure that had it been caught at the early stages, would have saved you thousands of dollars and countless hours in a repair shop.

Oil and fluid analysis is a common practice with trucks, busses and other vehicle fleets, providing invaluable information to protect their equipment.

Transmissions

According to Allison Transmission “Oil analysis plays an essential role in monitoring and understanding the general condition of the transmission and transmission fluid/filter system.” Just as with your engine, analyzing the oil in your transmission will provide you with valuable information that will alert you to potential issues before they become large issues.

According to Allison Transmission “Oil analysis plays an essential role in monitoring and understanding the general condition of the transmission and transmission fluid/filter system.” Just as with your engine, analyzing the oil in your transmission will provide you with valuable information that will alert you to potential issues before they become large issues.

If there is something going on in your transmission you want to understand that in its early stages. If your oil has broken down or is not performing at the level it should, you could see wear on your transmission’s components that will shorten its life and lower performance. Oil analysis and understanding your transmission oil’s viscosity and contamination will provide you indicators on what’s happening early.

Cooling Systems

The coolant system is often one of the most overlooked preventive maintenance items in an engine. Engine coolant maintenance is as important as oil maintenance. The condition of the coolant means everything to engine longevity. Today’s antifreeze-coolant not only protects from freezing in the winter months, but also helps protect diesel engines from common cavitation issues.

The coolant system is often one of the most overlooked preventive maintenance items in an engine. Engine coolant maintenance is as important as oil maintenance. The condition of the coolant means everything to engine longevity. Today’s antifreeze-coolant not only protects from freezing in the winter months, but also helps protect diesel engines from common cavitation issues.

According to Cummins as part of their filtration business. “Every good cooling system maintenance program should include regular coolant testing to determine if the proper level of protection is present or if contaminants exist. A good coolant testing program eliminates guesswork and allows the cooling system to maintain peak performance.”

An analysis of your coolant can detect:

- Metal corrosion

- Combustion gas leaks

- Contamination

- Electrical ground problems

- Localized overheating

- Air contamination

- Chemical breakdown

Another benefit with fluid analysis is that it can safely extend the use of your fluids between changes. Some people operate their RV differently, in varying conditions than what some of today’s fluids and equipment were actually built for, meaning you may be changing your fluids more than they need to be. For example, if you’re using your RV 4 times a year with a total of 3,500 miles your fluids might be in great shape after 12 months. For instance some RVer’s are getting over 20,000 miles between oil changes over a much greater period of time.

Here is a detailed document from our partners at JG Lubricant Services that really explains what determines the life of your oil. All About Oils for RV and Tow Vehicle Owners

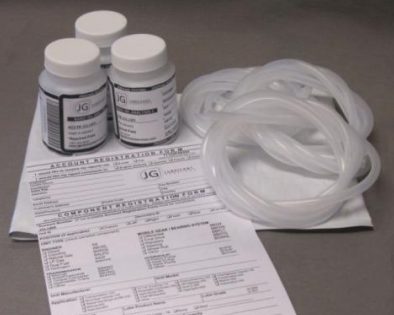

JG Lubricant Services has easy to use testing kits that will allow you to quickly draw your own samples. You can then send them into the laboratory for analysis using the included packing and sample identification form. In just a couple of days your results are available online for review and or downloading. You’ll see the specific measurement results from the tests as well as any recommendations based on your specific equipment and the test results. To get started we recommend you purchase:

JG Lubricant Services has easy to use testing kits that will allow you to quickly draw your own samples. You can then send them into the laboratory for analysis using the included packing and sample identification form. In just a couple of days your results are available online for review and or downloading. You’ll see the specific measurement results from the tests as well as any recommendations based on your specific equipment and the test results. To get started we recommend you purchase:

- One – Advanced Oil Analysis Kit (3-pack) (allowing you to test, engine oil, transmission oil, and generator oil) – $80.85

- Two – Coolant Analysis Kits – $69.16

- Two – Separate reusable vacuum pumps (red for oil, blue for coolant) $26.40 each

For a total investment of a little over $200 plus shipping, you are buying peace of mind in the knowledge of exactly how your key power system components are operating and the ability to detect potentially serious problems early. A great return on investment.

At Maintain My RV, a fluid analysis is part of every preloaded maintenance schedule so you can choose to easily incorporate them into your annual routines.

Using maintainmyrv.com to track and manage your maintenance schedule, including using regular fluid analysis, is a no brainer to maximize the life of your RV. For any RV to be safe, reliable and efficiently operating, regular preventive maintenance is critical. It is the most cost-effective way to keep your RV operating at peak performance. If you take care of your RV, then it and it’s components can last many years and have a far better resell value when it’s time to sell.

Take a proactive approach by planning for scheduled downtime, maintenance and repair costs. When you plan, you save money and time—and who couldn’t use more of each?